LOGO! Application of PLC in constant temperature and humidity unit

Author:Lianzhong | Release time:2021-06-15

1、 project introduction

The rotary dehumidifier is widely used in many industries, and most of the control schemes follow the DDC standard control scheme. However, Chinese customers need many combined dehumidification systems DDC is difficult to expand due to the limited control points and lack of flexibility. In order to meet the diverse control requirements of Chinese customers and provide the best control system for customers, through standardizing the controller and solving the problem of unified spare parts, our company finally chooses Siemens intelligent logic controller LOGO! As the controller of the series of dehumidification unit of the runner.

2、 Introduction of process flow

The system consists of precooling/ Preheating, wheel dehumidification and aftercooling/ The afterheat is composed of three parts

1) Precooling/ preheat

The relative humidity of air is close to saturation state during the cooling process. When the required temperature is reached, the excess water higher than the saturation state of the air temperature will be precipitated, so as to achieve the purpose of cooling and dehumidification.

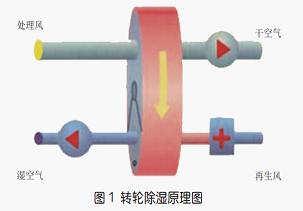

2) Wheel dehumidification

As shown in Figure 1 The dehumidification runner is divided into treatment area and regeneration area in dehumidification section internal sealing system, and the whole dehumidification is a continuous process. When the treated air passes through the treatment area of the runner, the water vapor is absorbed by the moisture absorption medium in the runner, and the water vapor changes at the same time, and releases latent heat. The other air first rises to the regeneration temperature through the regeneration heater, and then evaporates the adsorbed water in the runner through the regeneration area of the runner, and restores the dehumidification capacity of the runner; After that, the regeneration air becomes wet air due to the evaporation of water and is discharged out of the room through the regeneration fan.

3) Back cold / Afterheating: use cooling or heating to control the supply air temperature.

3、 Scheme determination

In order to realize the above control system, the alternatives are DDC control and PLC Control and logo! Control 3 Species:

1)LOGO! Comparison between DDC control and DDC control

① The system needs more than one DDC to complete, using LOGO! A main module can be realized by adding the corresponding expansion module.

② DDC control input and output point less, logo! There are many input and output points, and the switching analog can be expanded freely.

③ DDC control function solidification, can't change, logo! The user program can be written according to the needs, which has good flexibility.

④ DDC display interface fixed can not be changed, logo! According to the user's needs, we can design parameter modification setting interface and alarm interface.

2)LOGO! Control and PLC Control comparison

①PLC Without a display screen, text or screen is needed to realize the setting function of user parameters, which costs too much.

②PLC Must use computer to edit program and parameter, logo! In addition to supporting computer programming, CPU can also be used Integrated multi-function panel editing program and parameters.

③ And PLC Control comparison, wheel dehumidification constant temperature and humidity system needs less points, use logo! More cost-effective. To sum up, logo! Compared with DDC and PLC, the controller is more suitable for Rotary Dehumidification constant temperature and humidity unit.

4、Introduction of control systematization

According to the control requirements, the system uses LOGO! 24 as the main controller, expanded 3 Three modules, namely LOGO! DM8 12/24R , LOGO! AM2 PT100 and logo! AQ2。

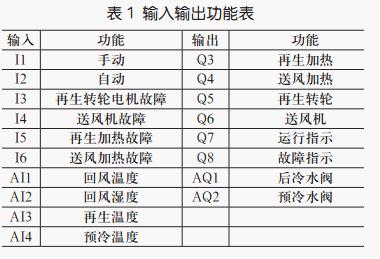

1) Introduction of input and output functions

The input and output distribution of the system is shown in Table 1 As shown in.

2)LOGO! Procedure description

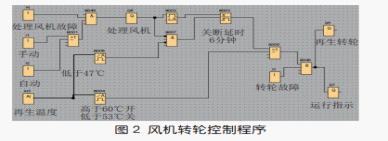

According to the control flow chart, the program can be divided into fan control, precooling, regeneration runner and aftercooling/ The rear heat is divided into four parts. Figure 2 Control procedure of fan runner

① Fan start and stop control

As shown in Figure 2 As shown in the figure, after the startup delay of the treatment fan, the regeneration fan and the runner motor are started. According to the actual situation of the site, the temperature and delay time of shutdown can be modified, which is very flexible.

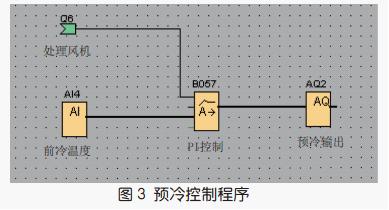

② Precooling control

As shown in Figure 3 As shown in the figure below, under the premise of the operation of the treatment fan, according to the pre cooling temperature PI Adjust the pre cooling water valve to control the pre cooling temperature.

③ Regenerative runner control

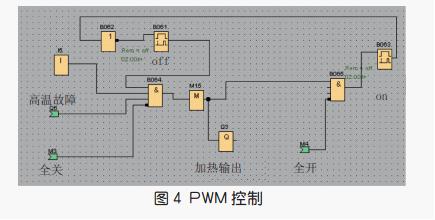

The control of the dehumidification capacity of the runner is realized by adjusting the regeneration heating and controlling the regeneration temperature. The dehumidification capacity of the runner increases with the increase of the regeneration temperature, and the regeneration temperature is 120 ℃ ~ one hundred and forty The dehumidification efficiency is the best when the temperature is between 0 ℃ and 0 ℃. The regeneration temperature is controlled by controlling a group of electric heating, and PWM (pulse width modulation output) function is generally used. LOGO! By calling PWM Function block, as shown in Figure 4 As shown in.

Figure 5 It shows the realization of regeneration temperature control PWM Turn on / off time program.

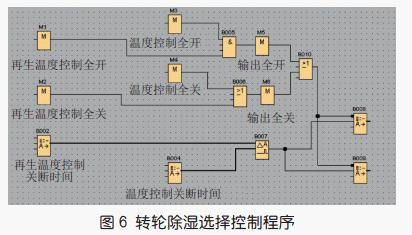

Regeneration temperature output and humidity output are all 3 The forms are: full open, full off, time proportion. The form of two outputs determines the final heating output form, as shown in Figure 6 As shown in.

The program design has two modes of "manual" and "automatic". In the automatic mode, the humidity and regeneration temperature control work at the same time, so as to save energy; In the manual mode, the wheel dehumidifier only controls the regeneration temperature. This function is realized by "analog multiplexer" function block. ④ Control of aftercooling and afterheating of unit

Similar to the control of the precooling and regeneration temperature mentioned above, it will not be repeated here.

five Application experience

LOGO ! Logic intelligent controller, low price, reliable performance, convenient programming. The company uses LOGO! The controller optimizes the circuit, improves the reliability of the product, achieves the unity of the controller, and reduces the workload of purchasing and maintenance personnel.