Selection and design of rotary dehumidifier for drying soft capsule

Author:Lianzhong | Release time:2021-06-15

| Ma Haiqing, Wuxi Lianzhong humidity control and energy saving equipment Co., Ltd |

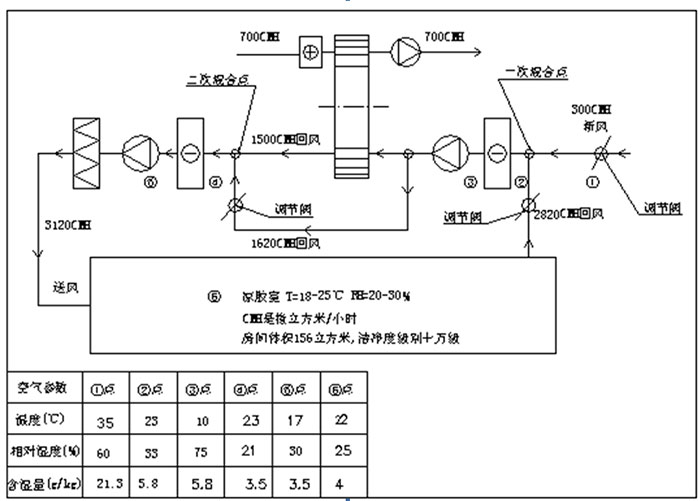

|

1、 Summary: there are several kinds of soft capsule drying technologies: ① rotary cage drying, ② track drying ③ static tray drying. As the static tray drying technology has the advantages of ensuring the surface gloss of soft capsules and no damage rate, it is a trend to adopt the static tray drying technology after four or five years of practical experience. Because the drying of materials is only related to the air temperature, humidity, wind speed and volatilization rate. Due to the factors of soft capsule itself, the drying temperature should not be too high, so in order to improve the production efficiency, we have to reduce the air humidity and increase the ventilation frequency in the drying room. In order to ensure the temperature, humidity, cleanliness, large air exchange times in the drying chamber of soft capsules and meet GMP standards, an artificial environment must be created to meet the requirements of the above four parameters. At present, domestic air conditioning manufacturers have no problems in ensuring the temperature, cleanliness and large air supply capacity in the drying room. It is difficult to control the low humidity. The humidity can be controlled at 50-70% in summer only by air conditioning. The best drying humidity of soft capsule is 20-30%. The general air conditioning and compression refrigeration dehumidifier (belonging to physical mechanical dehumidification) can not meet the humidity requirement at all. Chemical dehumidification must be used to meet this requirement. At present, the chemical dehumidification machine is the lithium chloride / silica gel / molecular sieve runner dehumidifier. Lithium chloride has been eliminated in foreign countries because of its strong corrosiveness, water soluble property and short service life; However, there are many reasons in China, some units are still using it. The traditional Chinese character of silicon gel is silicone, while silicon is the old name of chemical element silicon, rather than the silicone adhesive claimed by some sales companies. The development of silica gel dehumidification wheel is also slow in China, and it is not mature yet, and it is easy to fall off. The hygroscopic agent is only applied on the surface of fiber paper, and its moisture absorption efficiency is less than 20% of the mature products in the world. The mature products of imported silica gel Runner have about 6g/kg dry air per unit under the premise of 27-30 ℃ air inlet parameters, while domestic ones are only under 2g/kg dry air. Molecular sieve dehumidification wheel is suitable for extremely low air humidity of 1% - 10%, such as lithium battery manufacturing of mobile phone, special plastic industry, etc. Because the regeneration temperature of molecular sieve dehumidification runner is generally above 160 ℃, it is not suitable for general pharmaceutical enterprises because of its high energy consumption and high price. 2、 The design example of soft capsule drying room: 60m in area and 2.6m in height; It can hold about 350kg soft capsule; Drying time 35-40 hours; Cleanliness level 100000; Room temperature is 18-25 ℃, humidity is 20% - 30%; The temperature of dry bulb is 35 ℃ and the wet bulb temperature is 28 ℃ outdoor in summer; The air supply mode adopts the up and down return; Staff up to 4; No other wet source. 3、 Selection of dehumidifier: (1) determine the air supply volume of drying room: air purification and air purification according to air conditioning design manual In the relevant chapters of the clean room, when the cleanliness is 100000, the air change times of the room shall be designed at least 15 times / hour, and the design of this example is based on the number of air changes of 20 times / hour. Air supply volume l=20v=20 × sixty × 2.6m3/h=3120m3/h。 In order to improve drying efficiency, some users have increased the air exchange times to 30 times / hour. (2) calculate the moisture dissipation of drying room: check the air conditioning design manual to find out that the moisture dispersion in the drying room is in the room At 22 ℃, the light labor intensity, the adult's moisture dissipation is 150g/h, and the maximum indoor work is 4 people, that is, the maximum amount of moisture dispersion in the room is 600g / h. Because of the different varieties of soft capsules, their own volatilization rate is different, and the moisture dissipation is actually variable. Therefore, this example is designed on the premise of not putting glue in summer. The soft capsule manufacturer should make experiments to find out which temperature and humidity conditions the products have a faster drying effect and better effect, so as to determine the unit dehumidification quantity of the air supply. (3) determine the temperature and humidity of air supply: because there is no heat source in the room, and there are no other 4 staff members For other external humidity sources, the intermediate value required by the indoor is taken as the final design goal, namely, the design is based on the temperature of 22 ℃ and humidity of 25%. Considering the temperature rise of 5 ℃ of the air blower, check the relevant manual, and it is more appropriate to take the air supply temperature of 17 ℃. The moisture content of air supply shall not be greater than 3.8g/kg dry air after deducting the amount of moisture dispersion per hour of human body. (4) determine new air volume: determine the fresh air volume of clean room according to air conditioning design manual The maximum value of the following three conditions shall be taken: ① ensure positive pressure of the room; ② Ensure that the average oxygen intake per hour of staff members is not less than 45 cubic meters; ③ Take 10% of the total air supply. In summer, when the soft capsule is dry, the new air volume should be minimized because there is too much water in the fresh air. In order to avoid the infiltration of outdoor wet load into the room, positive pressure in drying room should be ensured. When the air volume of the supplementary air is 1-2 times of the air exchange rate of the room, the positive pressure difference of 5-10 PA can be maintained in the room relative to the outdoor. For this example, we take the supplementary fresh air volume of 300 m3 / h. (5) selection of dehumidifier: only air can be exposed by freezing and removing wet method of general air conditioning compressor The point temperature is reduced to 10 ℃, and the dew point temperature in the drying room of the soft capsule is below 1 ℃, so the general freezing and removing wet method can not meet the production process requirements. The air dew point temperature can be reduced to -40 ℃ easily by using the combination of air conditioning refrigeration and runner dehumidifier. (6) selection of cooling mode for air conditioning: water cooled refrigerator is suitable for more than 1000 square meters The large room or large system has a high cost performance; For the small room below 200 square meters, air-cooled pipe machine has many advantages, such as simple operation, convenient maintenance, no water supply and other advantages. The air-cooled pipe machine is suitable for the drying room of this example. (7) selection of regeneration mode of the runner dehumidifier: there are two regeneration modes of the runner dehumidifier at present The species are electric heating and steam heating. The pressure of the gauge heated by steam shall not be less than 4kgf/cm2. When steam heating and regeneration is selected, it is best to select high temperature resistant solenoid valve, which can not only realize automatic control to save energy, but also prolong the service life of dehumidification runner. When the actual air volume of dehumidification drying wheel is less than 2000 m3 / h, it is easier to choose the regeneration method of electric heating. (8) selection of refrigerator in front of dehumidification runner: mixing of fresh air 300m3/h and return air 2820m3/h The air temperature is 23 ℃, and the moisture content of air is 5.8g/kg dry air. When the air moisture content is constant, the lower the air temperature is, the better the dehumidification effect is. We reduce the mixed air to 10 ℃ and then send it to the dehumidification wheel. According to the relevant thermal formula, the refrigeration capacity of the front cooling machine is 13.52kw, so the refrigerator is selected. (9) selection of dehumidification drying wheel: check the technology of dehumidifier of u.s.motors. company of the United States Manual: when the air temperature of air inlet is 10 ℃ and the air moisture content is 5.8g/kg dry air, the specification is passed φ seven hundred and seventy × After the silica gel runner of 200 is treated, the air moisture content of the air outlet is 1.2g/kg dry air, which is far lower than the requirement of 3.8g/kg dry air of the air supply. The dehumidification runner of this specification is relatively large. In order to save energy and initial investment, we should choose the smaller one appropriately φ five hundred and fifty × The 200 dehumidification runner is checked and calculated. φ five hundred and fifty × The rated treatment air volume of 200 is 1500m3/h, so the other 1620 m3/h air needs to be bypassed. The air moisture content after mixing is 3.5g/kg dry air, which is close to the requirement of 3.8g/kg dry air in the air supply. Therefore, this type of dehumidification runner is selected. (10) selection of refrigerator after dehumidification runner: the air temperature after dehumidification runner is 23 ℃, including The wet volume is 3.5g/kg dry air, and the air supply temperature is 17 ℃, and the cooling capacity is 7.28kw according to the relevant thermal formula. Therefore, the refrigerator is selected. (11) filter selection: according to the actual situation of the project, the primary and medium efficiency filters shall be selected. (12) selection of fan: calculate each filter, evaporator of front and rear refrigerator, dehumidification runner The total resistance of air supply and return pipes and high efficiency air supply outlets shall not be less than 1200pa. Check the performance curve of 4-72-3.6a fan. When the air supply volume is 312m3/h, the total pressure is 1500pa and the total residual pressure of the system is less than 300pa. In order to ensure the air supply, increase the air pressure and improve the drying efficiency of soft capsules, a low noise full pressure air conditioner fan with a total pressure of 500pa is connected. Selection of control: through traditional relay contact control, single chip control, PLC The comparison of the years of practical experience of control shows that PLC is the best control method for the wheel dehumidifier. It has the following advantages: ① high reliability and strong anti-interference ability; ② It can realize the integration of electric control, electric instrument and electric junction; ③ The program is simple, easy to use, the control program is variable, and has good flexibility; ④ Small volume, light weight, low power consumption. In order to realize remote monitoring, touch screen or PC microcomputer can be added to control. 4、 Conclusion: After the calculation and consideration of the above 13 steps, the selection of a customized unit for desiccant air conditioning for drying soft capsules is completed. The shell of the integrated unit shall be insulated board. At present, the original 50mm sandwich board is generally used by all manufacturers. The insulation layer includes polyethylene foam and polyurethane foam. The polyurethane foam can resist high temperature, but its price is twice that of polyethylene foam. See the attached figure for the specific air treatment process. Reference: air conditioning design manual, the tenth design and Research Institute of the Ministry of electronic industry; Wuxi Lianzhong humidity energy saving equipment Co., Ltd. "technical manual of wheel dehumidifier" and so on. Attachment: air treatment flow chart of dehumidification air conditioning and purification unit

|