Two energy saving design measures of the wheel dehumidifier

Author:Lianzhong | Release time:2021-06-15

Abstract: This paper describes two energy-saving measures of active silica gel and molecular sieve rotary dehumidifier, fully analyzes the waste heat utilization of rotary dehumidifier, makes up for the shortcomings of energy consumption of rotary dehumidifier, and widens the application of rotary dehumidifier in food and pharmaceutical industry.

Key words: waste heat utilization, plate type heat exchanger, heat pipe heat exchanger, condensation heat

1. Overview: in the food and pharmaceutical industry, many production and processing processes must keep the air humidity below 45%, so as to produce qualified products. If the production of penicillin powder needle needs air humidity to be kept below 28%; The drying of soft capsule needs air humidity to be kept below 30%; The cooling packaging of citric acid needs air humidity to be kept below 15%, etc. in order to keep the air humidity below 45%, the double-stage dehumidification method combining the runner dehumidifier and air conditioning cooling and dehumidification must be used. The advantage of adopting the runner dehumidifier is that it can obtain low temperature and low humidity air, and the disadvantage is that the runner dehumidifier consumes a lot of energy due to the need of regeneration. At present, the dehumidifier runner is divided into three types because of the different hygroscopic agents: lithium chloride, active silica gel and molecular sieve. Because of the strong corrosiveness and easy solubility in water, the hot air for regeneration is not suitable for recycling. The active silica gel and molecular sieve are non corrosive, and renewable energy can be recycled. The regeneration waste heat can be recovered by plate type heat exchanger or heat pipe heat exchanger, so as to reduce the renewable energy. Because of the special energy consumption of the wheel dehumidifier, most users use local dehumidification. When local dehumidification is adopted, the refrigeration capacity of dehumidification unit is mostly below 100000 kcal/h, so the direct evaporation type is used in the refrigeration mode. The direct evaporation refrigerator has condensation heat, and the runner dehumidifier needs the regenerative heat source. So it is a good energy saving measure to use the condensation heat as the regenerative heat source of the runner dehumidifier.

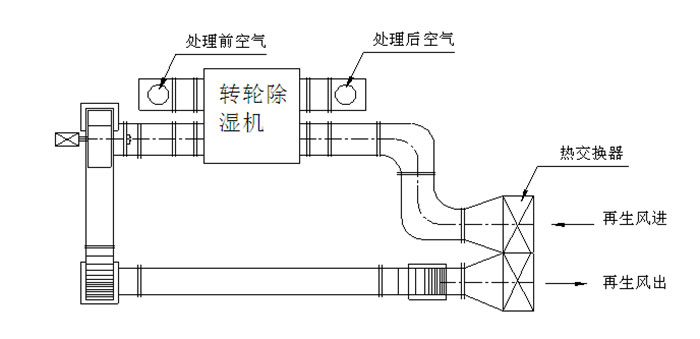

2. Waste heat utilization of regeneration air of the runner dehumidifier (see Fig. 1):

① Power consumption when exhaust gas from regeneration system is not recovered:

The rated treatment air volume of usd-30d runner dehumidifier of Lianzhong ECW is 5000cmh (cubic meter / hour, the same below), the regeneration air volume is 1700cmh, the regeneration temperature of silica gel dehumidifier is 140 ℃, and the regeneration air temperature is calculated as 20 ℃, and the energy consumption per hour of this runner dehumidifier is (140-20) × one point zero one × one thousand and seven hundred × one point two ÷ 3.6 = 68680 (W), and the power consumption per hour is 68680 ÷ 0.9=76311(W)。

② Power consumption of exhaust gas recovery from regeneration system:

When the regeneration heating temperature is 140 ℃, the exhaust gas temperature of the regeneration air is 70-80 ℃. Because the exhaust gas of regeneration air contains a lot of water, it is only used for the sensible part of the waste gas. The apparent heat recovery efficiency of plate or heat pipe heat exchanger is calculated as 60%. After the heat recovery heat exchanger, the fresh air temperature of 20 ℃ fresh air and exhaust gas rises to 62-68 ℃. We take the intermediate value as 65 ℃, and the power consumption per hour is (140-65) × one point zero one × one thousand and seven hundred × one point two ÷ three point six ÷ 0.9=47695(W)。

③ Savings in operating costs:

Energy saving per hour: 76311-47695=28616 (W). It is calculated by 150 days of operation every year, 8 hours per day, and 0.80 yuan for industrial power consumption. The annual operation cost saved is: 0.80 × eight × one hundred and fifty × 28.616 = 27471.36 yuan. At present, the market price of a 1700cmh plate type heat exchanger is RMB 5100.00, while the price of heat pipe heat exchanger only needs RMB 3500.00. Therefore, it can be seen that the runner dehumidifier with heat recovery device is economical and energy-saving.

④ Plate type heat exchanger:

The principle of plate type heat exchanger is to use 0.105mm thick anticorrosive aluminum foil as the base material; The corrugated plates of the unit are overlapped and bonded with the partition plate by glue. When there is a temperature difference between the two sides of the diaphragm, the heat transfer process will occur between the two sides. At present, the domestic technology of such products has been quite mature.

⑤ Heat pipe heat exchanger:

Heat pipe heat exchanger is a heat exchanger which is used to transfer heat by means of phase transformation of working medium (such as ammonia, acetone, methanol, etc.). Usually, the heat pipe heat exchanger consists of multiple heat pipes. In order to increase the heat transfer area, the tube is equipped with fins, and the wing to chemical ratio is generally 10-25. The number of heat pipe rows along the direction of air flow is usually 4-10 rows.

Figure 1 Schematic diagram of recycling of regenerative exhaust air by heat exchanger

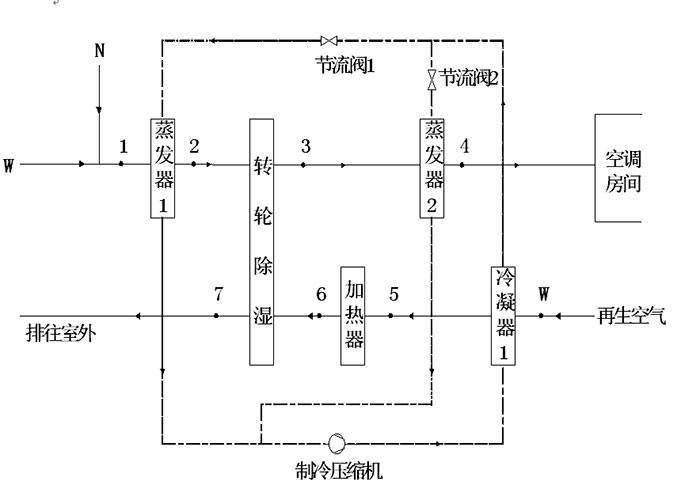

3. Recycling of condensation heat of combined rotary dehumidifier with air-cooled refrigerator:

Wheel dehumidification and cooling dehumidification have their own advantages. If they can optimize the combination and complement each other, they will play a better role. At present, some scholars at home and abroad have paid attention to this kind of combined dehumidification air conditioning system, which combines Rotary Dehumidification with cooling dehumidification. Some manufacturers of rotary dehumidifiers have made this improvement, such as the air-cooled rotary dehumidifier unit of Lianzhong ECW. However, how to make its structure more reasonable and operation more economical still needs continuous research and improvement.

① The characteristics of the combined dehumidification air conditioning system with runner and cooling

The combined dehumidification air conditioning system of runner and cooling combines the cooling dehumidification cycle system with the runner dehumidification system, which uses the heat absorption dehumidification of the refrigeration system for early dehumidification, uses the runner dehumidifier for deep dehumidification, and uses the heat release of the condenser to heat the regeneration air.

Figure 2 shows the schematic diagram of the rotary wheel and cooling combined dehumidification air conditioning system. The comparison between runner and cooling combined dehumidification air conditioning system and cooling dehumidification air conditioning system: cooling dehumidification has good dehumidification effect in a certain range, and the performance is stable, but when the humidity is required to be low, the evaporation temperature is very low, and the dehumidification capacity is reduced. At this time, the runner and cooling combined dehumidification air conditioning system can achieve good results.

Fig. 2 Schematic diagram of rotary wheel and cooling combined dehumidification air conditioning system

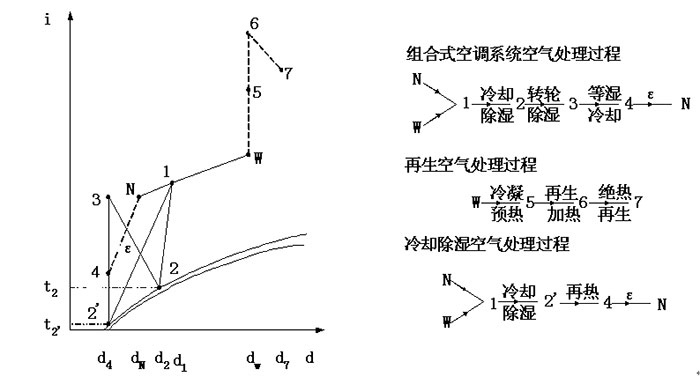

Fig. 3 air dehumidification process

It can be seen from Figure 3 that the dry bulb temperature of 2 points is much higher than that of 2 ', that is, the evaporation temperature of cooling and dehumidification in the combined air conditioning system is higher than that of the cooling and dehumidifier. When the dew point temperature corresponding to 4 points is lower than 0 ℃, the surface of the evaporator is easy to frost by using the cooling and dehumidification air conditioning system, but the combined air conditioning system is not limited by the dew point temperature, Therefore, when the dew point temperature of the air supply state is lower than 0 ℃, the combined air conditioning system with runner and cooling is much better than the single cooling dehumidification system.

② Characteristics of combined wheel and cooling dehumidification air conditioning system

I cooling dehumidification as early dehumidification, highlights the cooling dehumidifier under high dew point conditions

The utility model has the advantages of low energy consumption and the cooling coil is not easy to frosting.

II. Deep dehumidification with wheel dehumidifier, highlighting the low temperature and humidity conditions of wheel dehumidifier

In this case, it is not limited by dew point and has the advantages of large amount of dehumidification.

Thirdly, the condenser of the cooling and dehumidification circulation system is used to heat the regeneration air and make full use of it

The internal heat energy of the system overcomes the disadvantage of large heat consumption in the regeneration of the rotary dehumidifier, and finally achieves the purpose of energy saving.

IV. low temperature heat sources such as solar energy and industrial waste heat can be used as regenerative heating sources,

Reduce the dependence on electricity, and save a lot of energy.

reference:

(1) practical heating and air conditioning design manual edited by Lu Yaoqing

(2) papers of 2004 Annual Conference on heating and ventilation simulation and analysis of off design steady state performance of runner and cooling dehumidification combined air conditioning system

(3) product manual of heat pipe heat exchanger of Wuxi Beixi air conditioning equipment Co., Ltd

(4) product manual of rotary dehumidifier of Wuxi Lianzhong humidity control and energy saving equipment Co., Ltd.